Towards Urban Manufacturing for Circular Economy

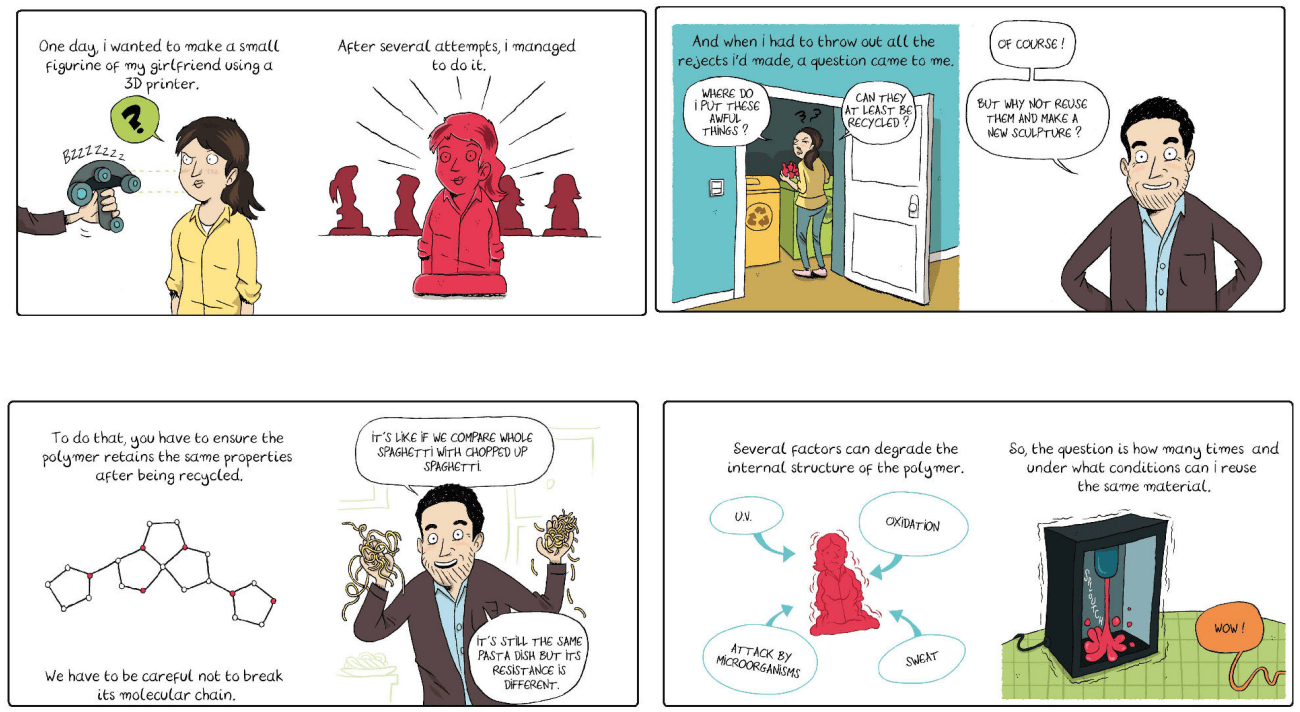

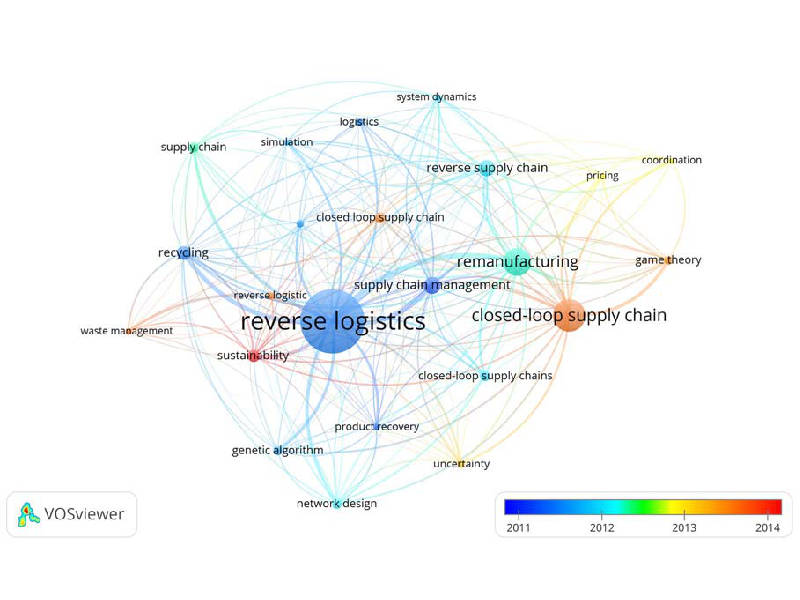

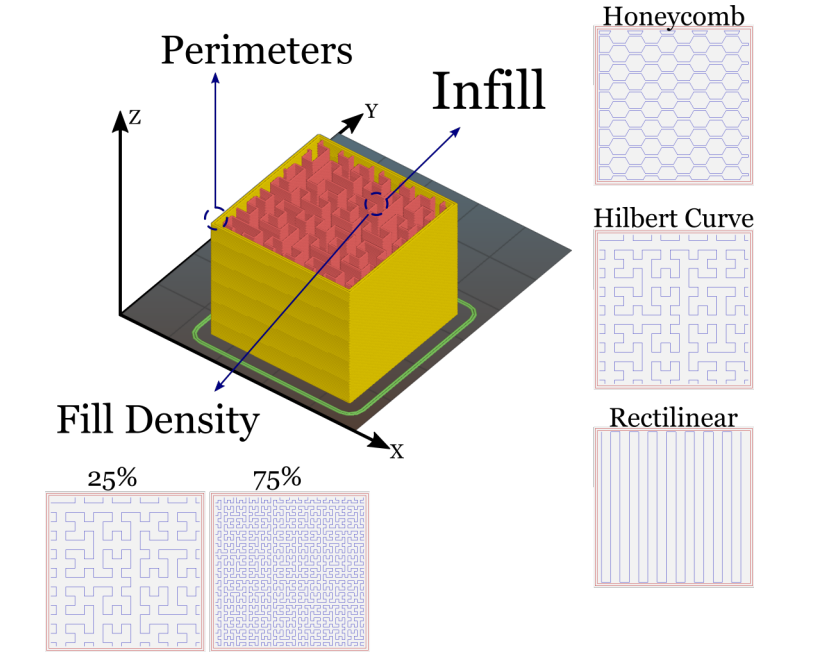

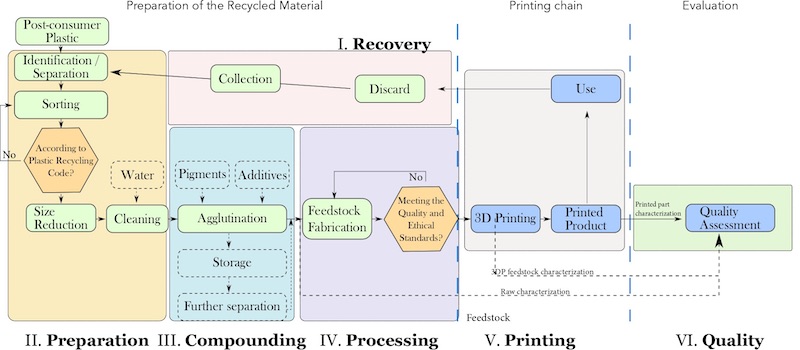

The concept of Green FabLab is the intersection of several societal trends. From one side, there have been a growing interesting in the additive manufacturing technology (a.k.a 3D printing) technology. The creation of the fantastic RepRap Projet, an open source project, opened up many possibilities in terms of local manufacturing. Also, the impact of the human activity to the environment and natural resources scarcity is taking more and more place in the general conscious. Therefore, a central issue today is how preserve material resources to in terms of circular in order to preserve the as much as possible

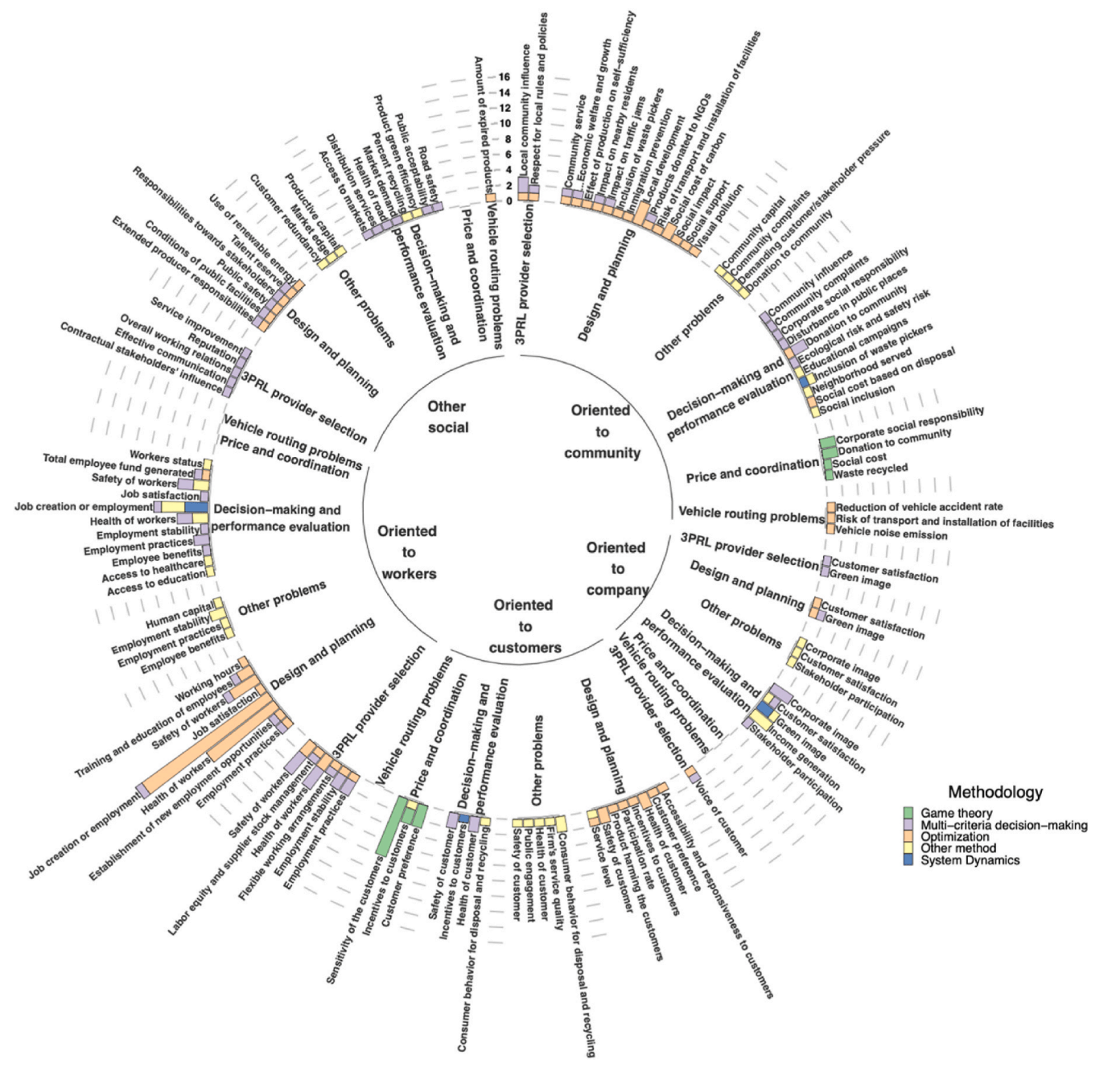

And finally, urban manufacturing approaches are actively utilizing the unique characteristics of its surroundings. They are creating products with a focus on the local market and allows customer involvement during value creation.

The Urban Factory has a minimal negative impact on its environment while positively influencing the local economy.

Third places as Urban Manufacturing

The concept of urban production requires a holistic approach and the incorporation of several involved disciplines. The city-factory-product nexus introduced in the beginning contains the three subsystems city, factory and product and their most basic interactions. The city-factory-product nexus is embedded in a larger city-production system. Within this system, definitions can be found of resources that are utilized by all subsystems in different ways and thus shared in the urban space

Our research

2015-09-01

2015-09-01